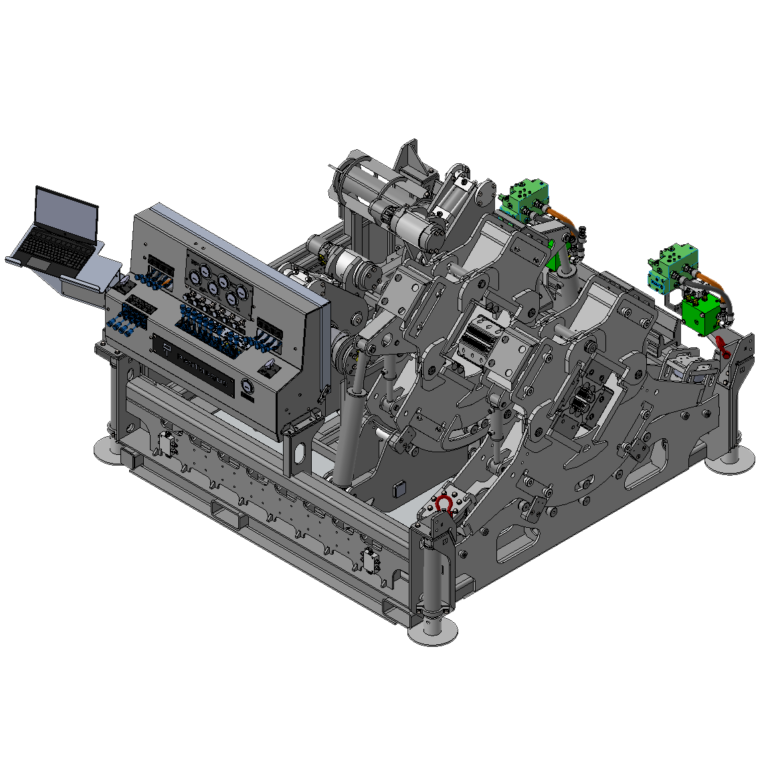

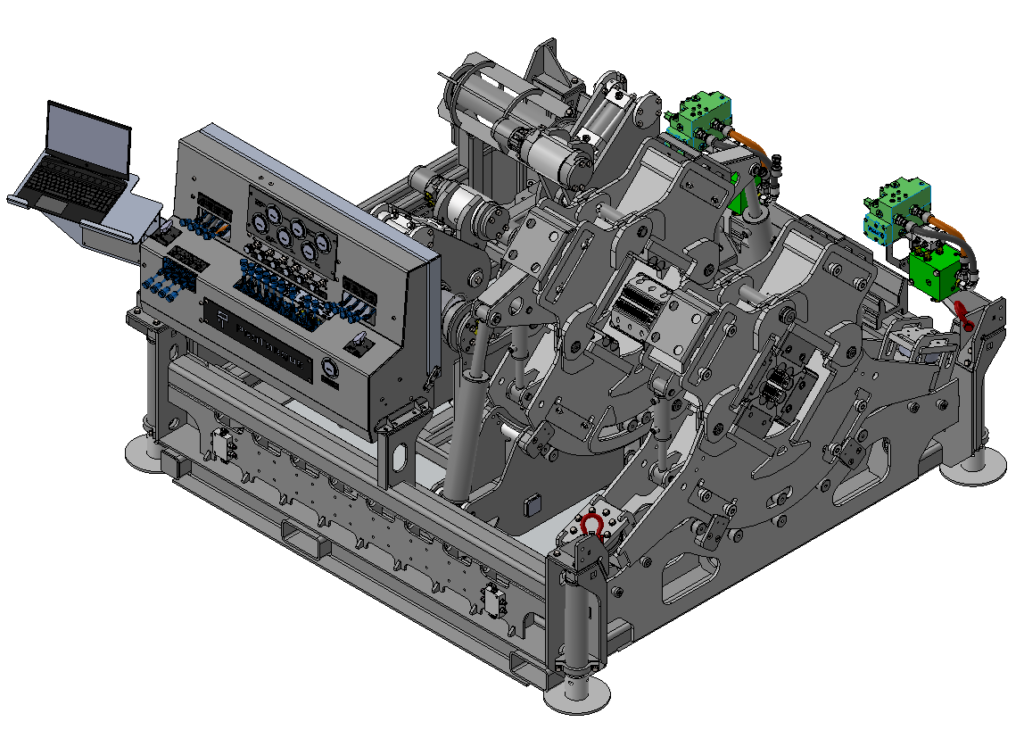

MOBILE BOTTOM HOLE ASSEMBLY (BHA) FRAME

The ProTorque BHA frame brings all of the make and break capabilities of a shop bucking unit and puts them in a mobile package. The frame can be shipped direct to your sites rather than shipping individual items to and from locations. The bucking frame consists of a tubular spinner, hydraulic stationary backup and a torque head with an adjustable span of up to 18 inches between the jaws. The four jaw design can accommodate pipe from 4 ½”” – 12” and up to 100,000 ft/lbs of torque. The frame safely assembles and disassembles any rotary shouldered connection(s). It is designed to assemble the bottom hole assembly offline. The horizontal position allows the operator to safely and easily align the threaded connection off the critical path. This reduces risk to employees on the rig floor as well as the chance of damage upon make-up or break-out, because the process is carried out off the critical path. The ProTorque Mobile BHA frame makes the process safer, saves valuable rig time and helps to reduce cost. All connections are able to be torque monitored, and a copy of those make up charts will be available on site.

The BHA frame is just another innovative way. ProTorque is redefining TRS. By striving for advancements in technology within our industry, we are known as one of the most technically advanced casing running solutionists on the market.

#RedefineTRS™

FEATURES

Single application savings up to 65%

Increase safety on rig floor

Efficient Use of Time (EUT)

Mobile design for direct on-site deployment

Run double or triple stands of drill pipe to save rig time

Reduce Carbon Footprint

SPECIFICATIONS

Heading #3 | Heading #3 |

|---|---|

PIPE SIZE RANGE | 4 ½”-12” |

TORQUE RANGE | 100,000 ft/lbs |

WEIGHT | 10,100 lbs |

DIMENSIONS | 95”L X 90”W X 57”H |

BACK-UP JAW ADJUSTMENT (SCOPE) | 18” |

ALL SERVICES, ALL LOCATIONS

Contact Us today!