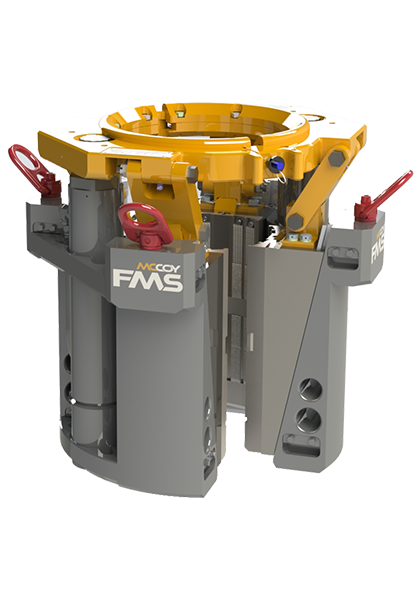

Flush Mounted Spider (FMS)

ProTorque offers the Flush Mounted Spider. This advanced rotary system delivers unmatched casing handling through replaceable die carriers and integrated back-up torque of up to 50,000 ft/lbs. Leverage streamlined, automated casing operations that outclass traditional methods.

#RedefineTRS™

FEATURES

Holds the weight of the casing string

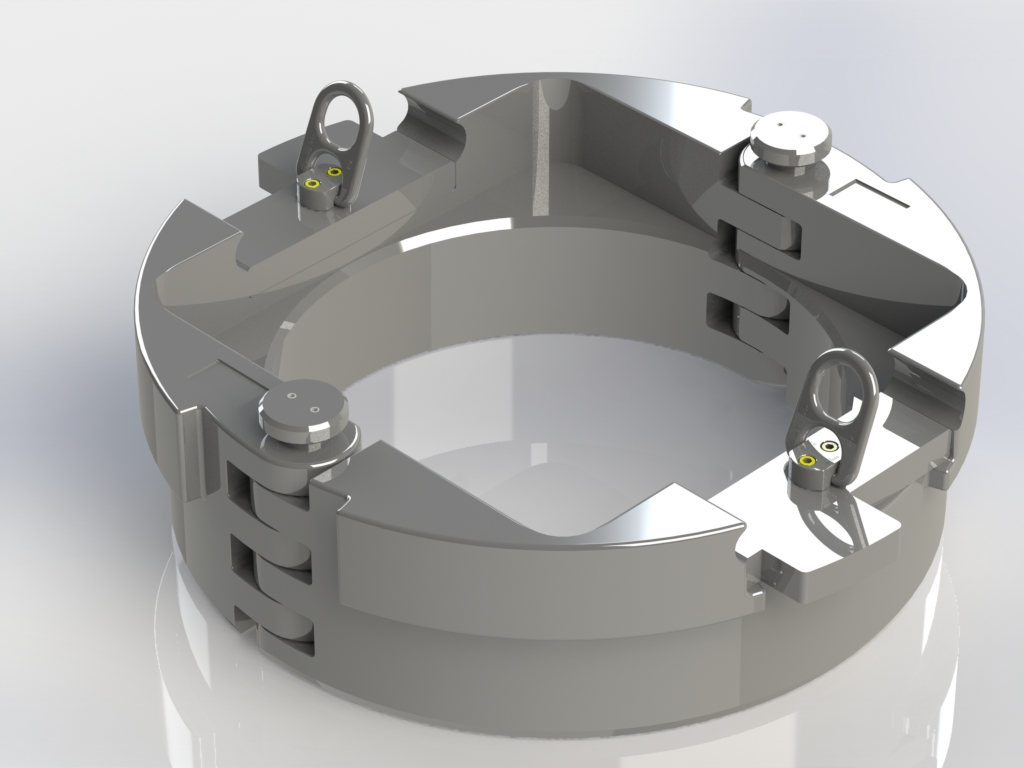

Replaceable die carriers for superior casing control

Powerful backup torque (up to 50,000 ft/lbs) eliminates the need for manual tongs and separate backup systems

Low-profile design integrates into the rotary table

Streamlined processes reduce pinch points and increase overall rig floor safety

SPECIFICATIONS

* With addition of the adapter ring, same FMS can be used with any other most common 37 1/2″ rotaries: national or EMSCO configuration

Heading #3 | Heading #3 |

|---|---|

MAXIMUM TENSION RATING | 350 TONS |

MAXIMUM WORKING PRESSURE | 2000 PSI (13,790 kPa) |

FLOW RATE REQUIRED | 34 GPM (128 LPM) |

MASS (TOOL ONLY) | 2,900 LBS (1,315 KG) |

MASS RANGE (CARRIERS AND GUIDE PLATES INCLUDED) | 3,050-3,700 LBS (1,383-1,678 KG) |

TIME TO EXTEND AND RETRACT | 6 SECONDS |

COMPATIBLE ROTARY TABLE | 27 1/2”, 37 1/2* |

CASING SIZE RANGE | 13.625″ – 2.375″ |

*MAXIMUM TORQUE AT 2000 PSI WORKING PRESSURE ON A SINGLE JOINT

* torque values are determined by slip upon the pipe and not the limitations of the tool

Heading #3 | Heading #3 |

|---|---|

MAXIMUM TENSION RATING | 50,000 |

MAXIMUM WORKING PRESSURE | 38,000 |

FLOW RATE REQUIRED | 30,000 |

MASS (TOOL ONLY) | 22,000 |

MASS RANGE (CARRIERS AND GUIDE PLATES INCLUDED) | 14,000 |

ALL SERVICES, ALL LOCATIONS

Contact Us today!