Vacuum Drifting

A Safer, Quieter Way to Confirm Casing ID Before Running

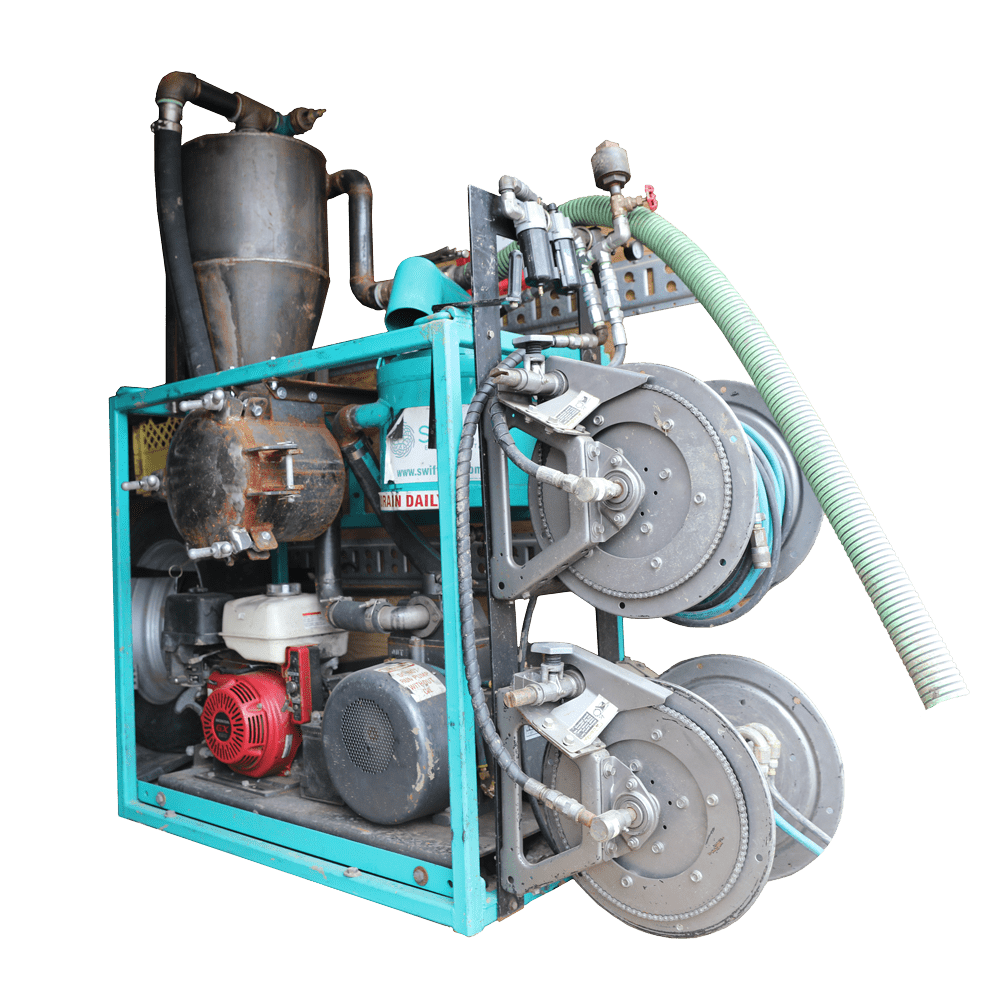

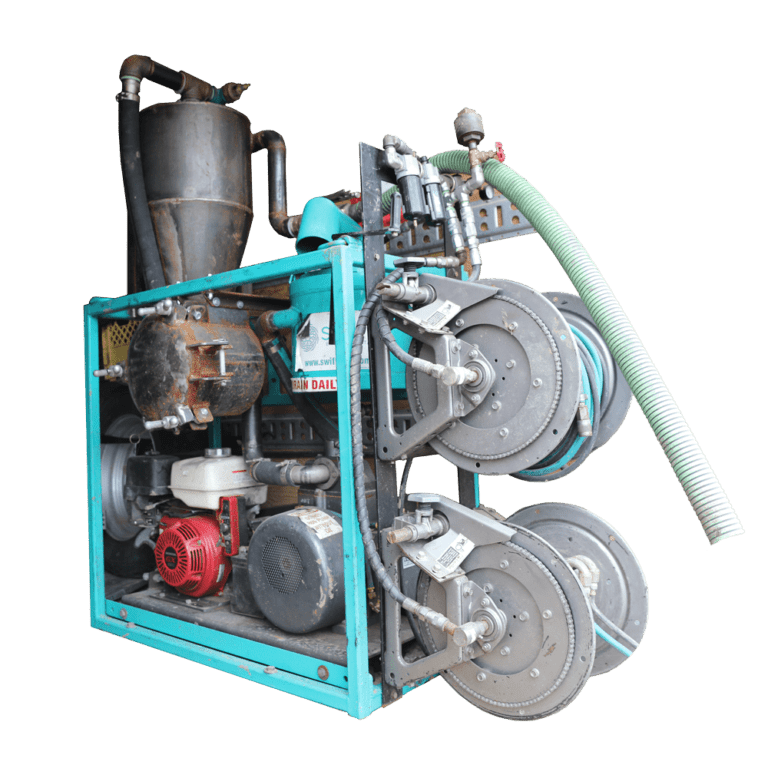

Vacuum drifting is a safer way to confirm casing inside diameter (ID) before running. Instead of conventional snake-and-drift handling, the drift is moved through the tubular using controlled vacuum force. The result is the same verification step crews rely on, with less manual handling exposure and less operating noise on location.

Why drifting matters before casing is run

Every casing program depends on one basic truth: the tubular has to pass what needs to pass. Drift confirmation is a simple step with outsized consequences, because the cost of finding an ID issue late is never small. It can mean delays, extra handling, and a lot of attention on the wrong part of the job.

That is why drifting exists. It is not a box to check. It is risk management.

The challenge is that conventional drifting can create its own exposure. Traditional snake-and-drift methods introduce pinch points, awkward body positioning, and a lot of manual interaction around tubular ends. It is one of those tasks that can feel routine until something catches, binds, or shifts.

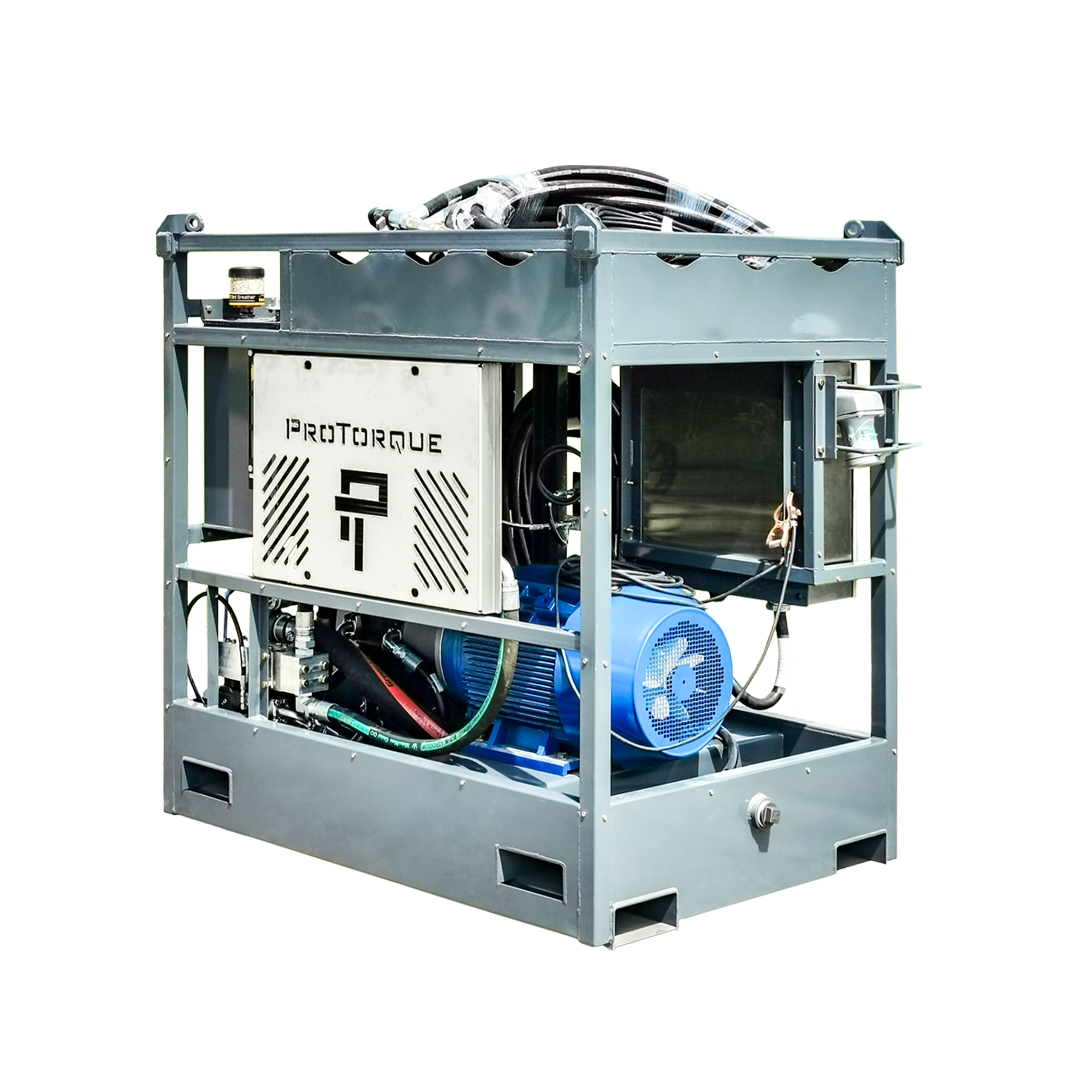

ProTorque’s approach to vacuum drifting starts with a straightforward goal: reduce manual handling exposure during casing preparation while keeping the casing ID verification step intact.

What vacuum drifting changes on location

With vacuum drifting, the drift is moved through the tubular using controlled vacuum rather than manual pull-through methods. Crews still confirm casing ID and identify deformities, but the process is designed to reduce the amount of handling required and reduce the conditions where minor issues become incidents.

It is a practical shift. The work still gets done, but in a way that supports safer execution and more consistent results.

A quieter system that supports clearer communication

Noise is often treated like a background problem on location, but it is a real operational factor. Communication and focus degrade as noise rises, especially during routine work where people are moving around the same area repeatedly.

The ProTorque Vacuum Drift System is designed to reduce operating noise by using a vane pump instead of a blower, and it can generate up to 27 Hg of vacuum force. That detail matters because it signals the system is engineered for measurable performance, not just convenience.

Built for real site conditions

Casing preparation does not always happen in the most convenient place. Space, access, and workflow vary. The vacuum drift unit is designed to be mobile and usable where the work is actually happening, including longer hose runs and areas that are harder to stage.

That mobility is more than a convenience. When a tool is easy to deploy, it is more likely to be used consistently. Consistency is where safety and reliability improve.

Control when the drift does not move freely

Any drifting method has to deal with the reality that a drift can lodge in the tubular. The vacuum drift system includes an adjustable reverse function to help push the drift back if it becomes lodged.

This kind of detail prevents a routine step from turning into downtime. It also reflects a tool designed around field conditions, not perfect conditions.

Key specifications for planning and fit

For drilling supervisors and TRS managers, a few specs quickly tell you whether a system fits your program. ProTorque’s Vacuum Drift System is designed to support a wide drift range, with controlled vacuum adjustment.

Key specifications include:

- Drift Range: 2.63 – 13.63” (66.8 – 346.2 mm)

- Vacuum Adjustment: 0 – 27 Hg (vacuum force)

- Size: Length 45” (1,143 mm), Width 30” (762 mm), Height 75” (1,905 mm)

- Weight: 400 lbs (182 kg)

- Hose Length: X2 100’

- 165 CFM @ 1,150 RPM

- 27 HG (Mercury units of vacuum force)

- 13 HP Honda motor

- Rubberized drifting ends for hoses

Where vacuum drifting fits in casing preparation

Vacuum drifting is most effective when it is treated as part of a clean, repeatable casing preparation process, not a standalone task.

In practice, drifting pairs naturally with casing cleaning and inspection work. When those steps are coordinated, casing is confirmed before it is staged for running, and crews reduce the chances of late-stage surprises on live operations.

Why this matters for HSE and drilling leadership

The value proposition is not flashy. It is practical.

Vacuum drifting supports leadership teams by reducing manual handling exposure during a routine step, improving consistency in casing ID confirmation, and maintaining clearer communication on location by reducing unnecessary noise. It also keeps the process moving by designing for real-world hang-ups instead of assuming ideal conditions.

It is one more example of a simple, engineered improvement that makes field work safer without slowing the job down.

Work with ProTorque

ProTorque supports vacuum drifting as part of its TRS service delivery across Canada and the US