Securing Rig Floor Safety

ProTorque’s Patented Tether Ring

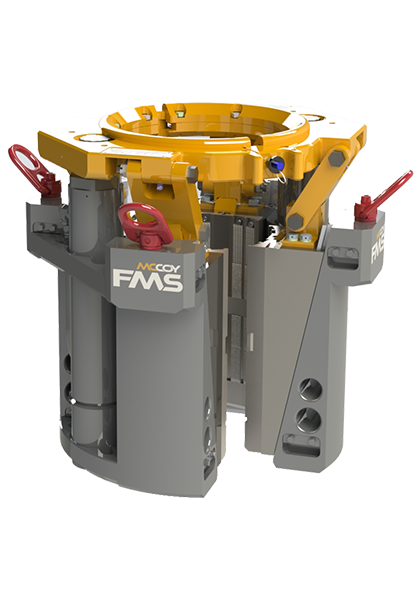

Ensuring safety on the rig floor requires advanced solutions designed specifically to address high-risk scenarios associated with tubular running services. ProTorque Energy has developed the patented Tether Ring, a critical safety tool that significantly reduces hazards associated with Casing Running Tool (CRT) operations.

Addressing Critical Rig Floor Risks

Tubular running operations involve handling heavy equipment and components suspended directly above rig floor personnel. If equipment becomes disengaged from the top drive, it creates a significant risk of dropped objects—posing immediate safety threats and potential operational disruptions.

ProTorque’s Tether Ring directly addresses these risks, providing an essential safeguard by securely connecting the casing running tool to the top drive assembly. If a CRT becomes detached from the top drive quill, the Tether Ring’s built-in anchor points and integrated safety slings ensure the tool remains safely suspended, eliminating the threat of a dangerous drop onto the rig floor.

Engineered Safety Features and Functionality

The patented design of ProTorque’s Tether Ring integrates critical safety components to provide reliable equipment securement during casing running operations:

Bolt-On Replaceable Anchors: Replaceable anchor points protect the grease port of the sealed bearing, featuring shock-absorbing design and a load rating capable of handling dynamic operational forces.

Secure Attachment and Shock Absorption: Integrated safety slings securely attach to bail anchors on the top drive. In the event of equipment detachment, these slings safely suspend the CRT, effectively eliminating the risk of a hazardous fall.

Interchangeable Components: The Tether Ring is adaptable to multiple CRT types, featuring interchangeable dies and anchor points. This allows damaged or worn components to be quickly replaced, extending the device’s useful lifespan and ensuring continued operational integrity.

Precise Performance Specifications

ProTorque’s Tether Ring is engineered specifically with operational safety and reliability in mind:

- Load Rating: 3,000 lbs (1,665 kg), effectively managing operational loads.

- Shock Rating: Capable of absorbing up to 40,000 lbs (18,182 kg) of dynamic force.

- RPM Capability: Operates effectively up to 120 RPM, ensuring securement under operational conditions.

Operational Flexibility and Efficiency

ProTorque’s Tether Ring is designed to seamlessly integrate into standard rig floor practices:

- Pre-Job Installation Flexibility: The Tether Ring can be installed either prior to arriving onsite or directly at the job location for immediate torque verification and setup.

- Effective Clamping Force: Engineered to apply precise, effective clamping with 7,500 lbs of bite force, securely engaging the casing running tool and maintaining stable positioning.

Safety Beyond Compliance

ProTorque’s Tether Ring does more than simply meet safety regulations. It actively contributes to safer operational practices by:

- Eliminating dropped-object hazards associated with CRTs.

- Supporting clear, confident operational practices by reducing crew exposure to dangerous conditions.

- Improving operational efficiency by minimizing interruptions and enhancing equipment reliability.

Integrated Training and Support

ProTorque recognizes that even the best-engineered equipment requires structured support. The company’s People Ops team ensures comprehensive competency training and detailed operational procedures accompany every Tether Ring deployment, providing personnel with the knowledge and skills required for confident and safe operation.

ProTorque’s Commitment to Operational Integrity

The patented Tether Ring represents ProTorque Energy’s deep commitment to safety and operational excellence. With proven functionality, exceptional adaptability, and detailed engineering, the Tether Ring ensures rig floor personnel and operational equipment remain protected at all times.