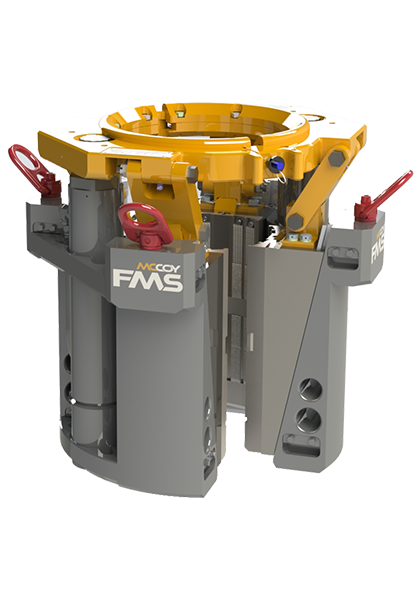

Flush Mounted Spider (FMS)

Flush Mounted Spider (FMS): A Safer, Smarter Approach to Casing Operations

In oil and gas, where every detail matters, even small changes can have a big impact. ProTorque’s Flush Mounted Spider (FMS) implementation is a solution designed to improve how casing operations are handled—bringing safety, efficiency, and precision front and center. Successfully implemented in the US and now being rolled out in Canada, the use of the Flush Mounted Spider showcases how ProTorque continues to push forward with practical innovations that solve real challenges on the rig floor.

What Sets the Flush Mounted Spider Apart?

The Flush Mounted Spider is a hydraulically operated slip system that integrates seamlessly into the rig floor. Unlike traditional systems that rely on manual slips or cumbersome equipment, the FMS simplifies and secures casing operations in three critical ways:

- Enhanced Safety for Crews

By eliminating manual slips, the FMS reduces the strain and risks typically placed on workers. Instead of workers manually pulling slips, the FMS allows operators to control the system hydraulically, removing physical hazards and ensuring greater consistency. The flush design also eliminates tripping hazards, creating a safer rig floor for everyone. - Streamlined Operations

The FMS doesn’t just protect workers—it works harder, too. It can hold up to 50,000 ft/lbs of torque on the first casing joint, allowing crews to skip the oversized equipment usually needed for early stages of a casing run. With the ability to automate key tasks like slip control, the FMS minimizes downtime and ensures smoother operations. - Learning from the US Rollout

The FMS has been rigorously tested in US operations, where valuable lessons have informed ongoing improvements. Adjustments to hydraulics, control systems, and operational procedures have made the tool even more effective. This refined approach is now being applied as we roll out Canadian deployments.

Canadian Rollout: Building on Success

ProTorque’s Canadian teams are preparing deployments of the FMS, leveraging the experience and insights from its US operations. By integrating feedback and adapting to specific rig conditions, we’re ensuring that the FMS rollout in Canada delivers the same operational and safety benefits.

A Better Way to Handle Casing

The FMS doesn’t just replace traditional equipment—it redefines the process. It reduces the need for multiple pieces of bulky hardware while enhancing the precision and reliability of casing operations. For clients, this means fewer delays, safer crews, and tools that are purpose-built to meet today’s demands.

Looking Ahead

ProTorque’s Flush Mounted Spider is just one example of how we’re improving everyday rig operations through smarter tools and better processes. If you’re interested in learning more about the FMS or how it can benefit your next operation, contact us today. Together, we can make every casing run safer, faster, and more reliable.