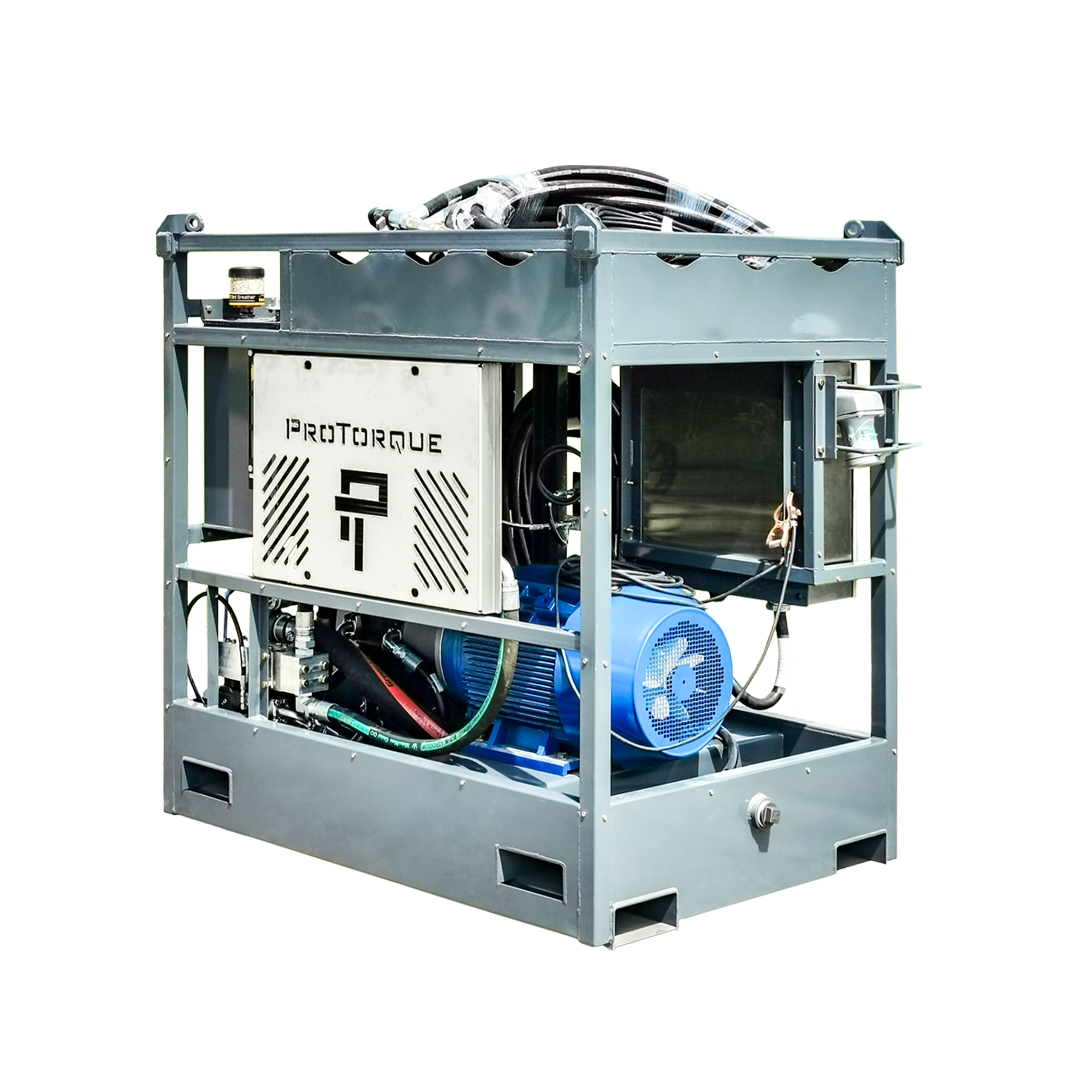

ProTorque Energy Midstream

Expertise and Precision: Our Approach to Midstream Construction and Maintenance

Successful midstream operations rely on experienced teams, precise execution, and meticulous planning. ProTorque Energy Midstream (PTEM) combines decades of technical expertise with specialized capabilities in constructing, upgrading, and maintaining midstream facilities and pipeline infrastructure.

Our management and field crews have extensive project experience spanning multiple oil and gas basins. This collective experience translates into efficient execution and reliable outcomes for facility owners and operators.

Proven Experience, Precise Execution

Our senior project managers and field supervisors bring deep, practical knowledge to every phase of facility construction and expansion projects. Clients routinely rely on PTEM’s capability to detail piping systems and create accurate, field-ready isometrics, significantly streamlining project timelines and reducing costly engineering cycles.

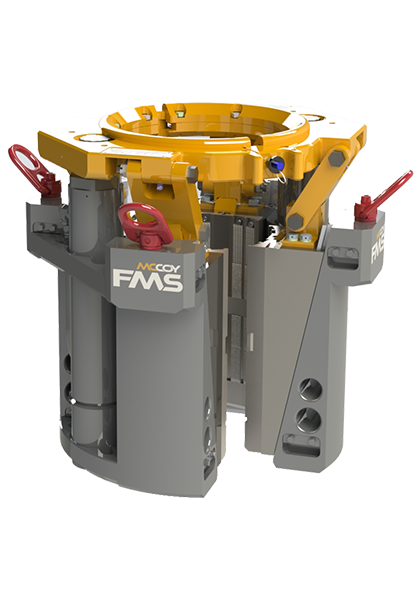

Specialized Capabilities

- Turnkey Facility Construction: From initial site preparation through to completion, ProTorque delivers fully integrated solutions.

- Pipeline and Facility Maintenance: Our rapid-response teams offer around-the-clock support, ensuring consistent uptime and operational continuity.

- High-Quality Pressure Welding: ASME and API-certified welding expertise to maintain integrity and safety in critical infrastructure.

Training Excellence Drives Performance

Central to our consistently high standards is ProTorque Energy Midstream’s dedicated training facility. Our structured, hands-on training programs ensure that every team member is fully competent in critical tasks, from welding certifications and procedure compliance to comprehensive equipment maintenance and safety practices. This investment in our workforce translates directly into safe, efficient, and high-quality project execution in the field.

PTEM’s teams understand the operational realities faced by the companies we partner with. Our depth of expertise, investment in personnel development, and emphasis on meticulous planning deliver tangible advantages—less downtime, fewer surprises, and consistently superior outcomes.