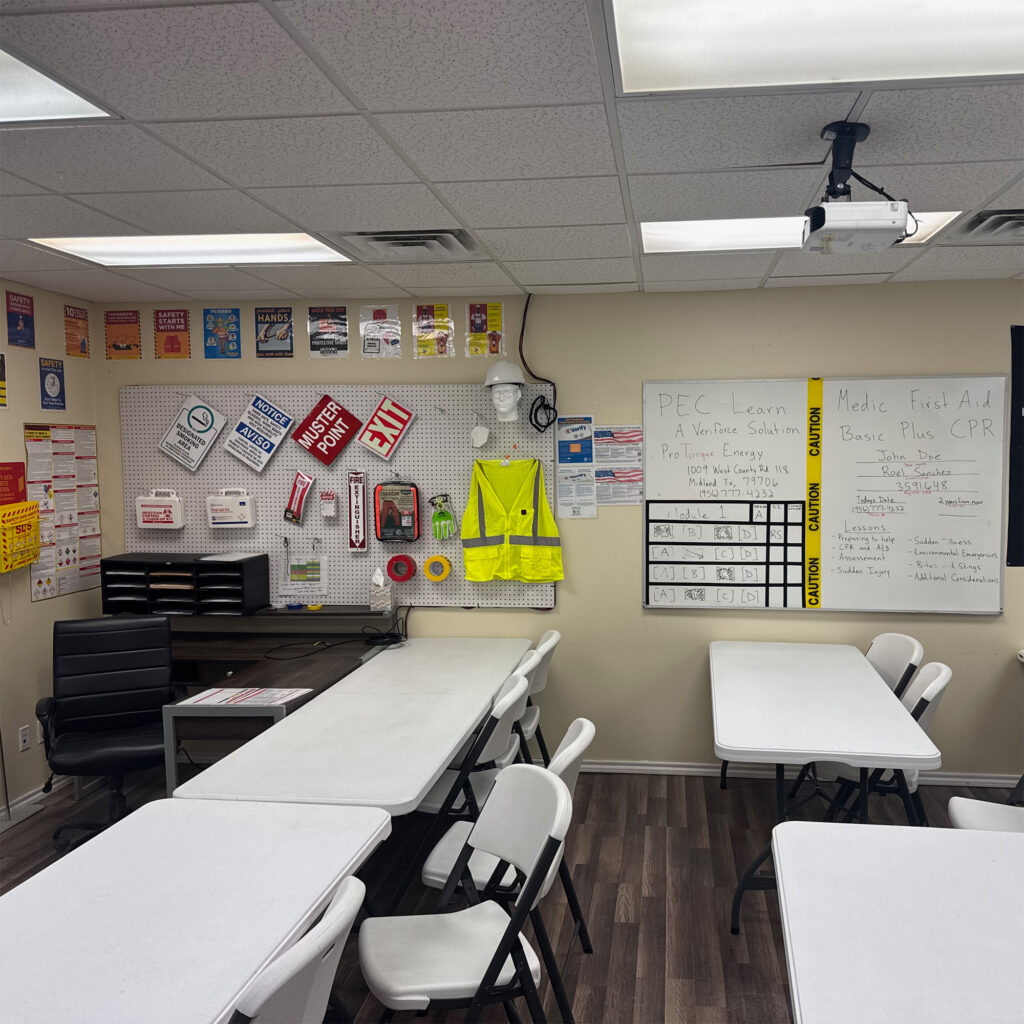

ProTorque Energy, a leading provider of Total Rig Solutions (TRS) and midstream construction services, is celebrating its 20th anniversary. Since 2004, ProTorque has established a reputation for delivering cutting-edge services, prioritizing safety, and fostering a culture of innovation within the oil and gas industry.

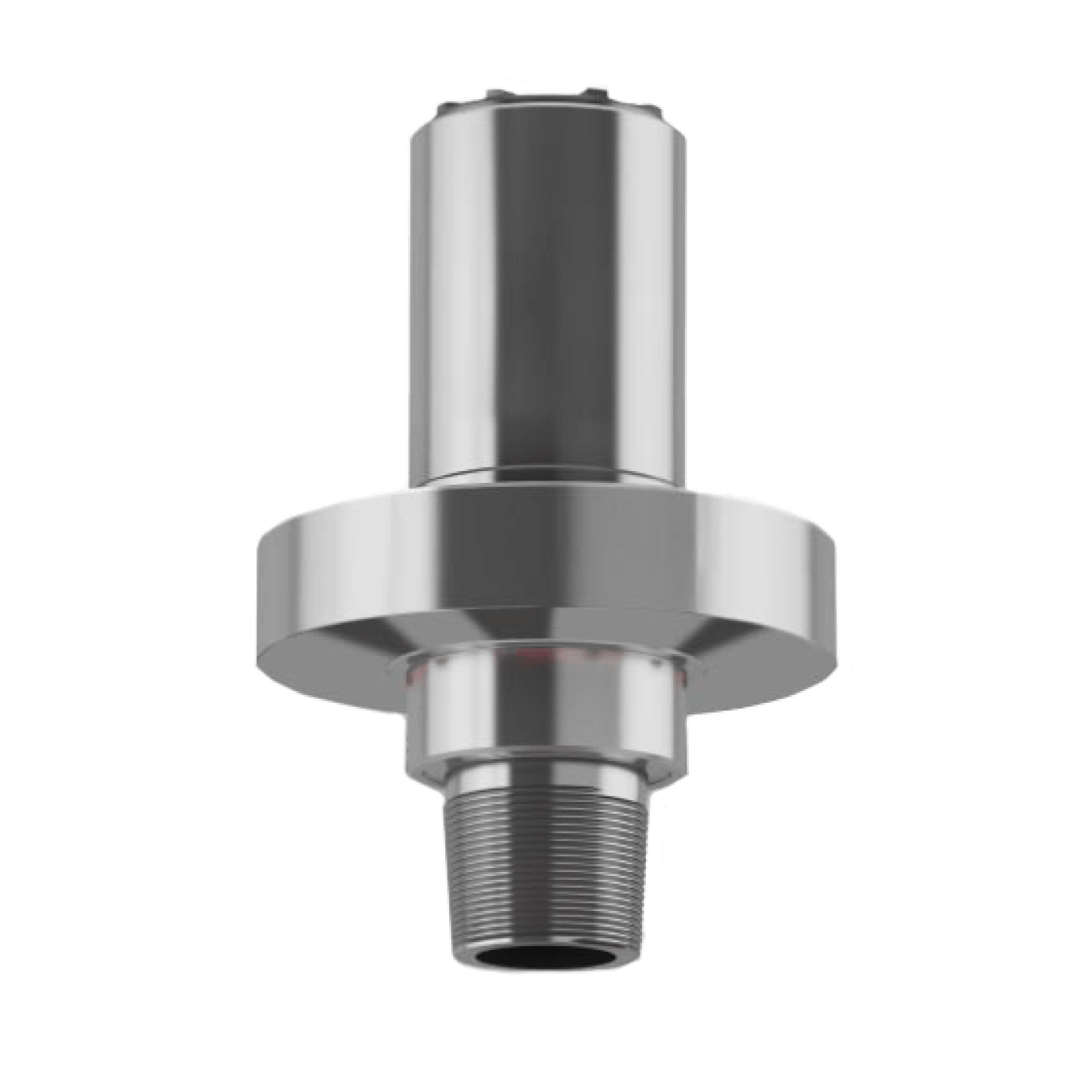

Continue reading- High-Quality Pressure Welding: We maintain ASME and API-certified welders for critical infrastructure. Our expert welding ensures the integrity and safety of pipelines and pressure vessels, meeting strict industry standards.

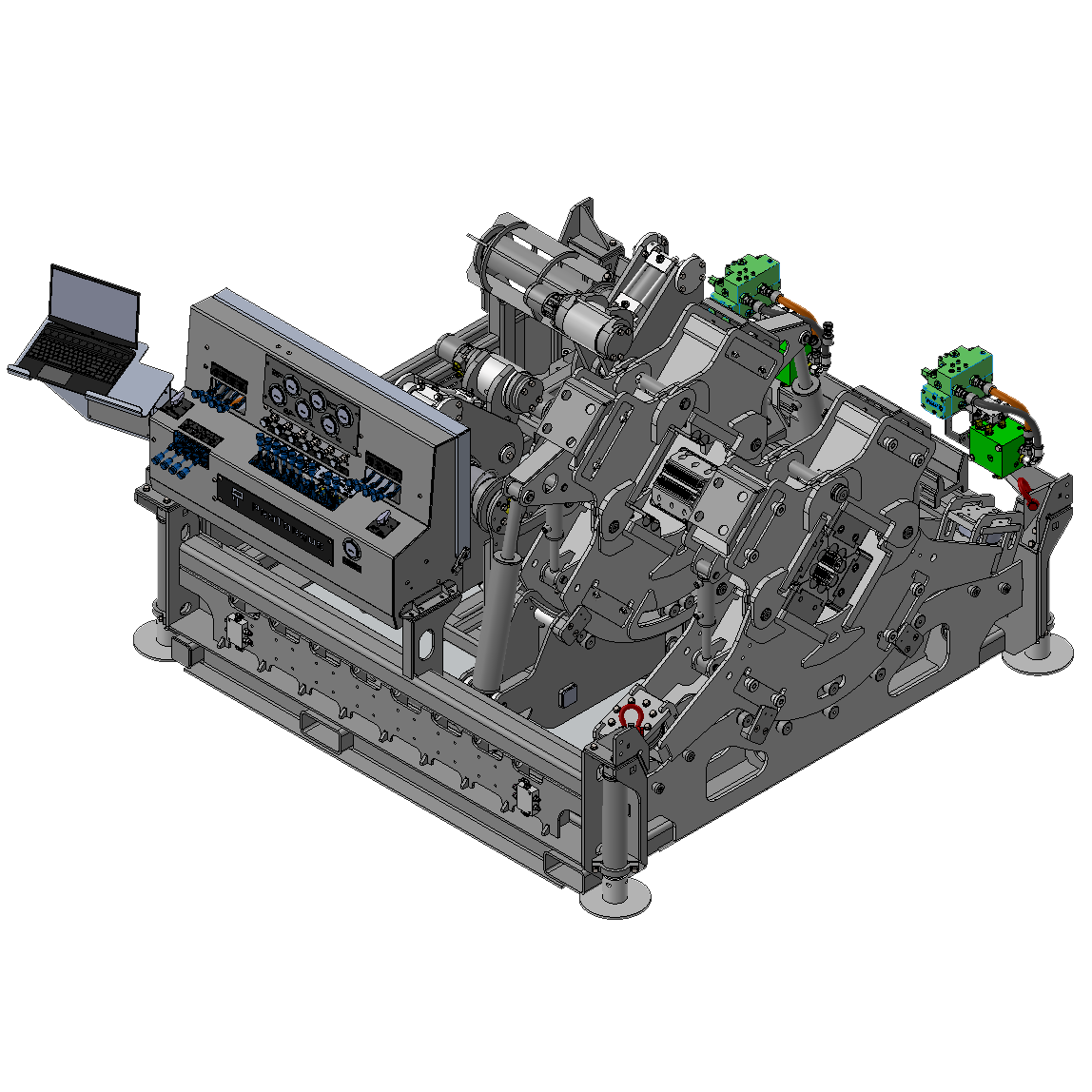

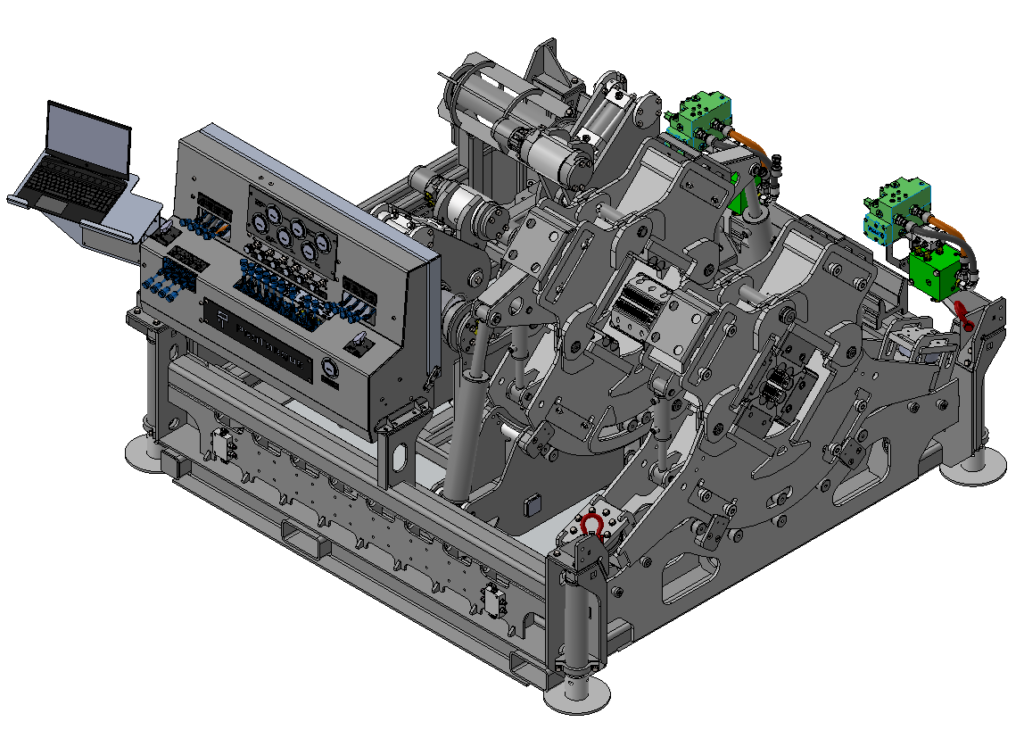

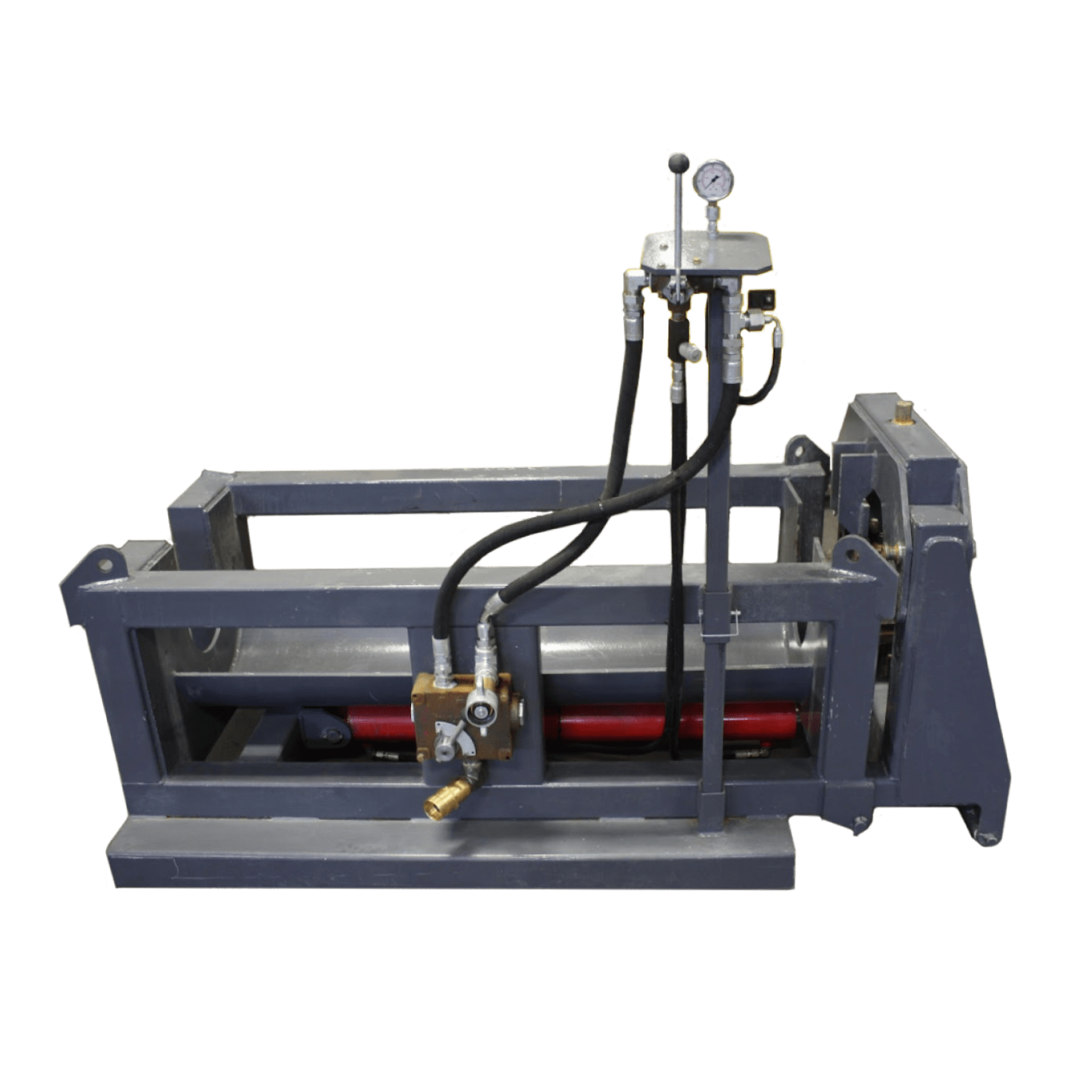

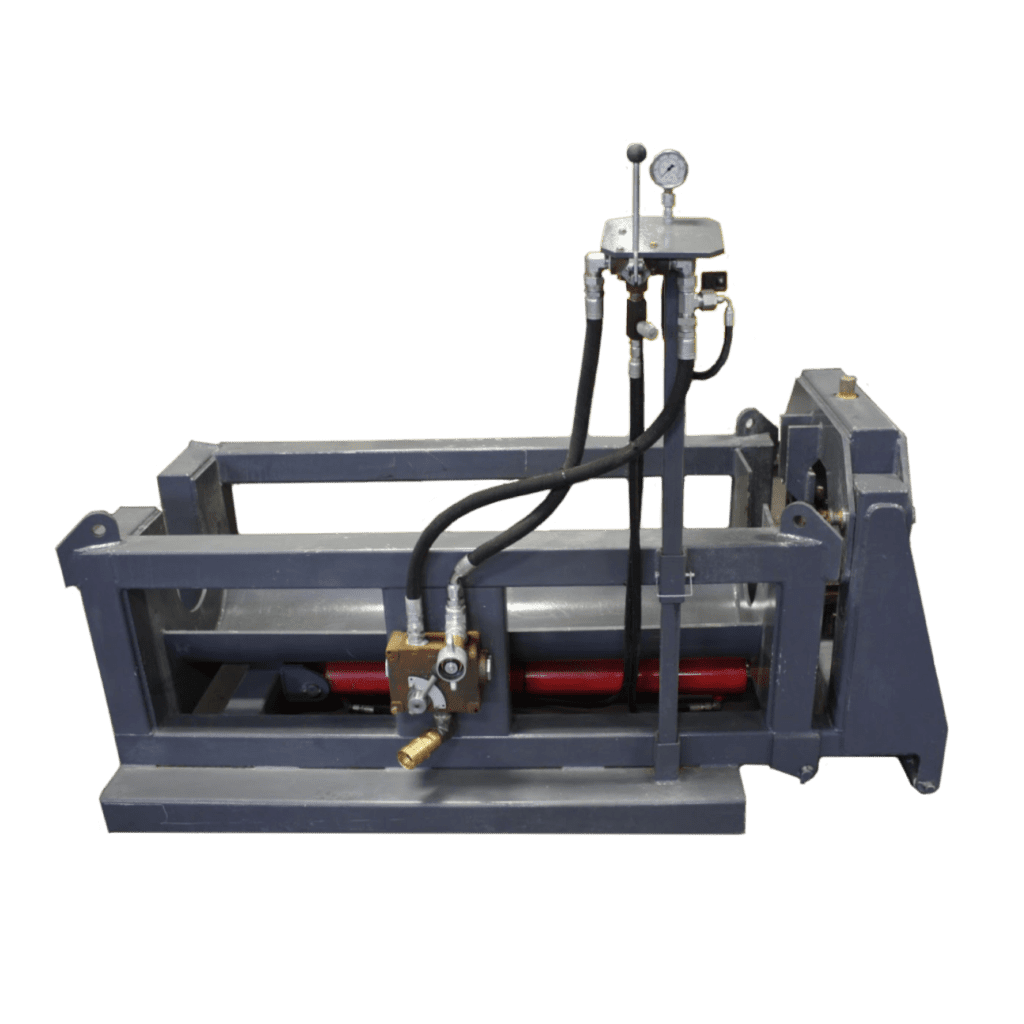

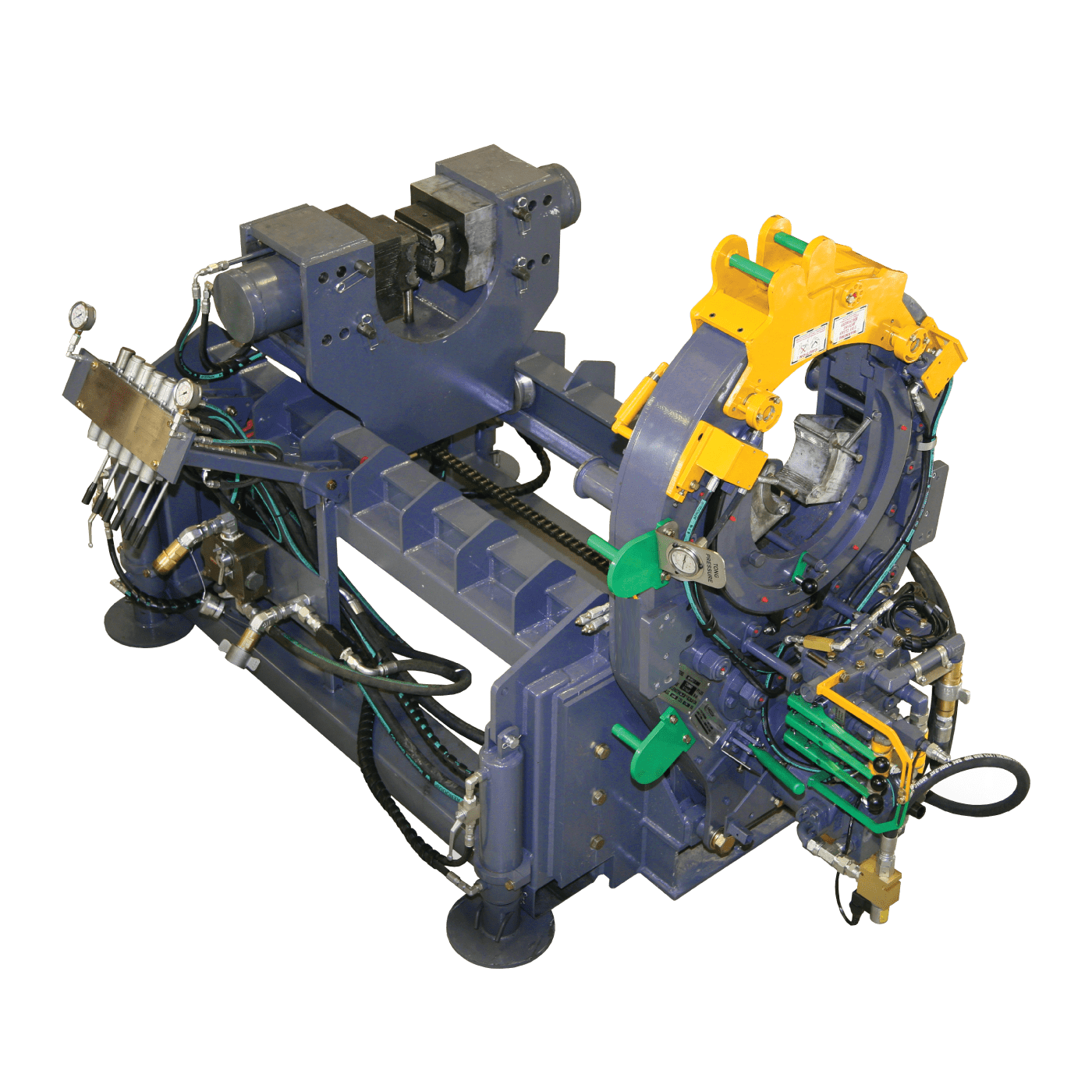

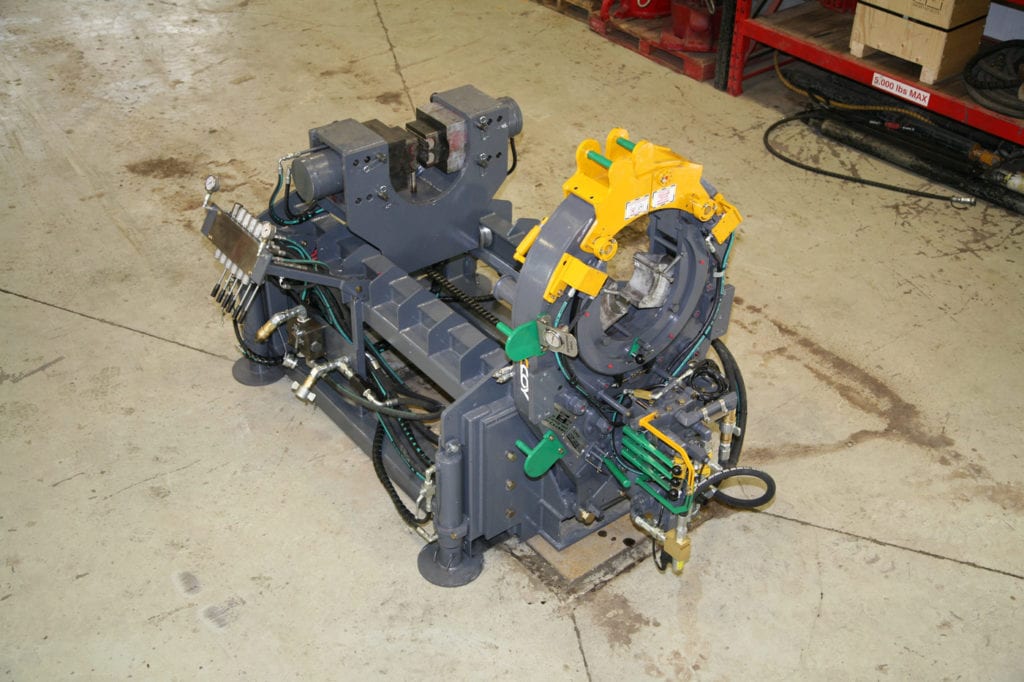

Midstream project execution often involves heavy machinery and skilled coordination. PTEM’s experienced crews and certified specialists ensure that construction and maintenance tasks are performed safely and efficiently, minimizing downtime.

This breadth of capabilities means fewer third-parties and handoffs, giving clients a single accountable partner for midstream projects. Our depth of expertise, combined with careful planning, delivers tangible benefits – less downtime, fewer costly surprises, and consistently high-quality results for our customers.